Resina Lavável Flashforge – 0.5L

28.00€ + IVA*

Boa resistência mecânica e equilíbrio rígido-resistente

Baixo encolhimento

Excelente desempenho em detalhes

Limpeza fácil (apenas com água)

Boa resistência ao calor sem rachaduras ou deformações (30 min a 100)

Pintura fácil

Boa estabilidade de armazenamento a longo prazo

Compatível com a maioria das impressoras 3D LCD

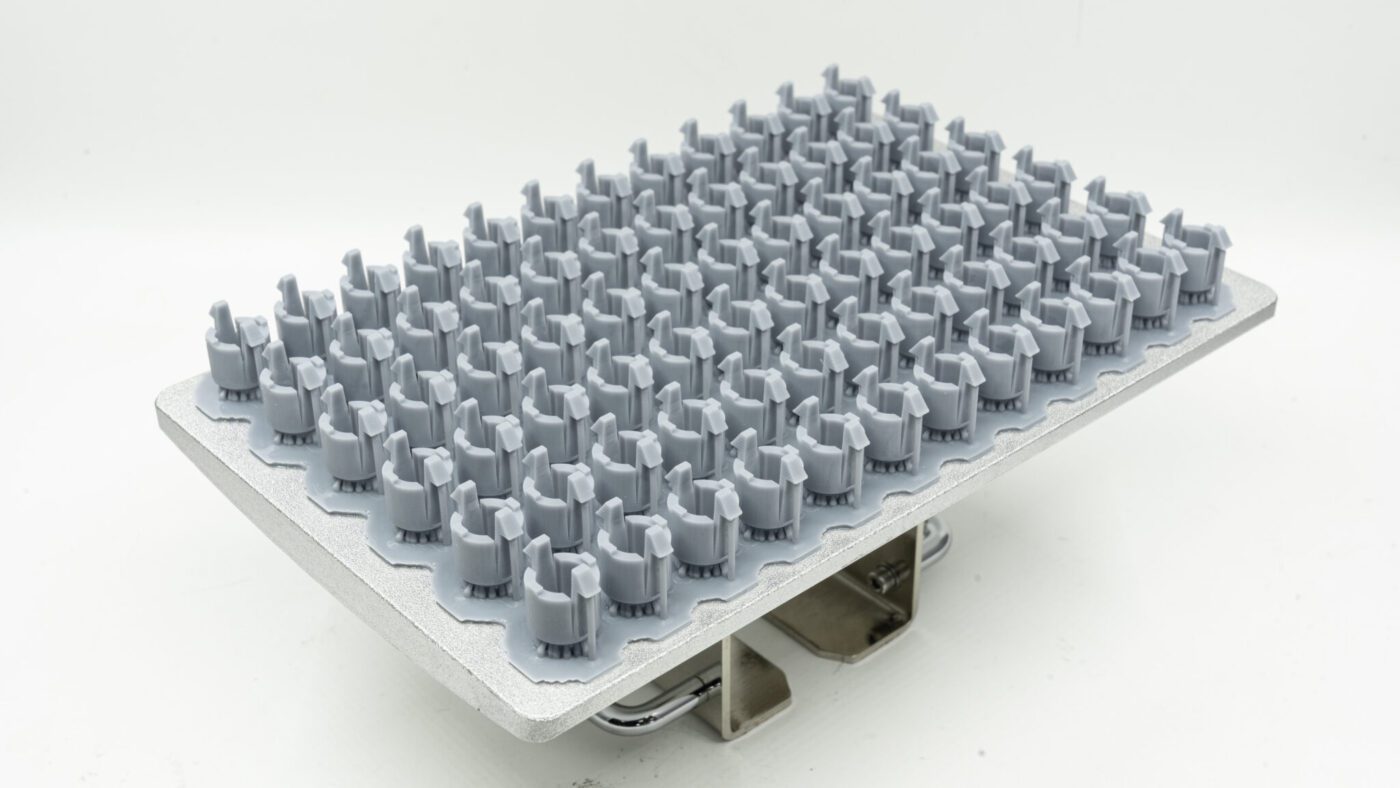

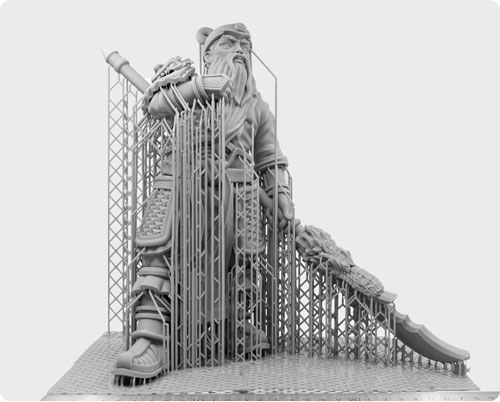

Laser Cladding Deposition (LCD) – a kind of technology that projects an image onto the liquid photosensitive resin and forming a solid layer with laser radiation and exposure. Using a pulling mechanism it pulls up a certain height (height equal to the layer thickness of the digital model) each time after the layer curing and exposure, making the currently cured solid resin layer adhere onto the former cured layers. A solid 3D model is printed out in this way. Compared with other technologies, the LCD 3D printing technology featuring plane surface curing and molding greatly improves 3D printing efficiency.

Advantages

Low odor

Fast curing

Wide compatibility

Good stability

Appropriate hardness

Easy to clean

Easy to color

Low shrinkage

Environmentally friendly

Applications

Printing figures

Prototyping verification

Production of small batches

| Resin Type | Water Washable Resin | Flexural Strength | 58 Mpa |

| Density | 1.13 ~1.24 g/ml | Viscosity | 160 ~220 cps, 25ºC |

| Shore Hardness | 84 D | Tensile Strength | 32 Mpa |

| Elongation at Break | 8% | Flexural Modulus | 2200 Mpa |

Shake evenly before use

Put on gloves while using photopolymer resin to avoid direct contact with hands

Avoid direct skin contact

Wash with water after touching the resin

Avoid lighting

Unused photopolymer resin needs to be stores in a dark, dry and cool place

| Peso | 0.68 kg |

|---|---|

| Dimensões (C x L x A) | 11 × 24.5 × 11 cm |

| Brand | Flashforge |